Share information:

Car engine overhaul Peugeot 406

Engine Specifications

cylinder head Maximum non-flatness of mating surfaces: – XU engines 0.05 mm – XUD engines 0.07mm Protrusion of the swirl chamber in diesel engines 0 - 0.03 mm valves Valve disc diameter Inlet valve: – gasoline engines:...

cylinder head Maximum non-flatness of mating surfaces: – XU engines 0.05 mm – XUD engines 0.07mm Protrusion of the swirl chamber in diesel engines 0 - 0.03 mm valves Valve disc diameter Inlet valve: – gasoline engines:...

Removal and installation of the engine and transmission

Attention! The engine can only be removed from a vehicle with a gearbox. Removing 1. Park the vehicle on a level surface, block the rear wheels, raise the front of the vehicle and support it on stands. Remove both front...

Attention! The engine can only be removed from a vehicle with a gearbox. Removing 1. Park the vehicle on a level surface, block the rear wheels, raise the front of the vehicle and support it on stands. Remove both front...

Removal and installation of engines with automatic transmission

Attention! The engine is removed from the car only with a gearbox. Removal is carried out in the same way as removal of an engine with a manual transmission, except for the following differences. Removing 1. Use a lever...

Attention! The engine is removed from the car only with a gearbox. Removal is carried out in the same way as removal of an engine with a manual transmission, except for the following differences. Removing 1. Use a lever...

Engine repair — general information

It is most convenient to work on the engine if it is installed on a special frame. Before repairing the engine, it is necessary to remove from it: generator; thermostat and coolant outlet pipe (gasoline engines);...

It is most convenient to work on the engine if it is installed on a special frame. Before repairing the engine, it is necessary to remove from it: generator; thermostat and coolant outlet pipe (gasoline engines);...

Removal and installation of a head of the block of cylinders (engine 2.1 l)

Removing 1. Remove the camshaft and pushrods. 2. Remove the intake and exhaust manifolds. 3. Remove the high pressure fuel pump pulley. 4. Remove the bolts and remove the engine mount from the front of the engine. 5....

Removing 1. Remove the camshaft and pushrods. 2. Remove the intake and exhaust manifolds. 3. Remove the high pressure fuel pump pulley. 4. Remove the bolts and remove the engine mount from the front of the engine. 5....

Dismantling of a head of the block of cylinders

1. Remove the cylinder head. 2. If not removed, remove the intake and exhaust manifolds. 3. Remove the camshaft, pushers and gaskets. 4. On diesel engines, remove the glow plugs. On 2.1 liter diesel engines, remove the...

1. Remove the cylinder head. 2. If not removed, remove the intake and exhaust manifolds. 3. Remove the camshaft, pushers and gaskets. 4. On diesel engines, remove the glow plugs. On 2.1 liter diesel engines, remove the...

Cleaning and inspection of the cylinder head

Attention! If the engine has been overheated, it is possible that the cylinder head is deformed. Therefore, it must be carefully checked. Cleaning 1. Remove the remnants of the old gasket from the cylinder head. 2....

Attention! If the engine has been overheated, it is possible that the cylinder head is deformed. Therefore, it must be carefully checked. Cleaning 1. Remove the remnants of the old gasket from the cylinder head. 2....

Cylinder head assembly

1. Lubricate the valve stems with engine oil and insert them into place. Install the valves in the places where they were lapped. 2. Install the spring seat. Dip the slinger cap in fresh engine oil and install it over...

1. Lubricate the valve stems with engine oil and insert them into place. Install the valves in the places where they were lapped. 2. Install the spring seat. Dip the slinger cap in fresh engine oil and install it over...

Removing pistons with connecting rods

1. Remove the cylinder head, sump and oil pump. 2. If there is carbon on the top of the cylinder, remove it with a soft scraper. The presence of a step in the upper part of the cylinder indicates excessive wear of the...

1. Remove the cylinder head, sump and oil pump. 2. If there is carbon on the top of the cylinder, remove it with a soft scraper. The presence of a step in the upper part of the cylinder indicates excessive wear of the...

Removing the crankshaft

1. Remove the crankshaft pulley and oil pump. 2. Remove pistons and connecting rods. If the pistons and connecting rods will not be repaired, then there is no need to remove the cylinder head. 3. Check crankshaft end...

1. Remove the crankshaft pulley and oil pump. 2. Remove pistons and connecting rods. If the pistons and connecting rods will not be repaired, then there is no need to remove the cylinder head. 3. Check crankshaft end...

Cylinder block

Cleaning 1. Remove all parts and electrical sensors from the cylinder block. For complete cleaning, remove process plugs. To remove the plugs, drill small holes in them and screw a self-tapping screw into the holes....

Cleaning 1. Remove all parts and electrical sensors from the cylinder block. For complete cleaning, remove process plugs. To remove the plugs, drill small holes in them and screw a self-tapping screw into the holes....

Pistons and connecting rods — check

Piston group elements The correct location of the piston relative to the connecting rod on diesel engines Examination 1. Before checking pistons with connecting rods, remove the piston rings from the pistons and...

Piston group elements The correct location of the piston relative to the connecting rod on diesel engines Examination 1. Before checking pistons with connecting rods, remove the piston rings from the pistons and...

Crankshaft — check

Checking the crankshaft end play using a dial gauge Checking the axial play of the crankshaft 1. The end play of the crankshaft is checked when it is installed in the engine block. 2. Axial play is checked with a dial...

Checking the crankshaft end play using a dial gauge Checking the axial play of the crankshaft 1. The end play of the crankshaft is checked when it is installed in the engine block. 2. Axial play is checked with a dial...

Inspection of main and connecting rod bearings

Typical bearing defects 1. Even though the main and connecting rod bearings should be replaced when the engine is overhauled, they must be carefully inspected as they can provide valuable information regarding the...

Typical bearing defects 1. Even though the main and connecting rod bearings should be replaced when the engine is overhauled, they must be carefully inspected as they can provide valuable information regarding the...

Engine assembly sequence during overhaul

Engine assembly must be done in the following order: crankshaft; pistons-rods; oil pump; pallet; flywheel; cylinder head; drive belt tensioner and pulleys, as well as a drive belt; hanging knots.

Engine assembly must be done in the following order: crankshaft; pistons-rods; oil pump; pallet; flywheel; cylinder head; drive belt tensioner and pulleys, as well as a drive belt; hanging knots.

Installation of piston rings

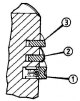

The location of the piston rings on the piston 1. Oil scraper ring 2. Middle O-ring 3. Top O-ring Before installing new piston rings, check the gap in the ring lock. 1. Position the pistons and piston rings according to...

The location of the piston rings on the piston 1. Oil scraper ring 2. Middle O-ring 3. Top O-ring Before installing new piston rings, check the gap in the ring lock. 1. Position the pistons and piston rings according to...

Selection of new crankshaft main bearings

XU series engine Decal location on XU engine block for main bearing selection A. Barcode (used in engine manufacturing) B. Designation signs On some engines, the upper and lower halves of the bearings were the same...

XU series engine Decal location on XU engine block for main bearing selection A. Barcode (used in engine manufacturing) B. Designation signs On some engines, the upper and lower halves of the bearings were the same...

Checking the working clearance of the crankshaft main bearings

XU series engine 1. On early models of engines, when overhauling, it is necessary to install new liners. On later engine models, running clearance can be checked using the original bushings. However, it is preferable to...

XU series engine 1. On early models of engines, when overhauling, it is necessary to install new liners. On later engine models, running clearance can be checked using the original bushings. However, it is preferable to...

Installing the crankshaft (XU and XUD engines)

1. Using engine oil, install the upper thrust washers on each side of the #2 main bearing with the oil grooves facing the crankshaft. 2. Install the bearing shells in place. Lubricate the bearing surface with clean...

1. Using engine oil, install the upper thrust washers on each side of the #2 main bearing with the oil grooves facing the crankshaft. 2. Install the bearing shells in place. Lubricate the bearing surface with clean...

Pistons installation

1. Check that the connecting rod bearings are correctly installed. If new bearings are installed, check that all traces of protective grease have been removed with an appropriate solvent. Wipe the bearings and...

1. Check that the connecting rod bearings are correctly installed. If new bearings are installed, check that all traces of protective grease have been removed with an appropriate solvent. Wipe the bearings and...

Starting the engine after a major overhaul

1. With the engine installed in the vehicle's engine compartment, check the engine oil and coolant levels. Check that all previously removed wires and hoses are installed in their places. Gasoline engines 2. Remove the...

1. With the engine installed in the vehicle's engine compartment, check the engine oil and coolant levels. Check that all previously removed wires and hoses are installed in their places. Gasoline engines 2. Remove the...

This section is available on russian, bulgarian, belarusian, ukrainian, serbian, croatian, romanian, polish, slovak, hungarian

See similar information for other Peugeot models

➨ Power unit: Engine repair Peugeot 207 (2006-2014)

➨ Power unit: Overhaul of petrol engines Peugeot Partner I (1996-2008)

Link to this section in different formats

TEXTHTMLBB Code

- General information

- User manual

- Maintenance (gasoline)

- Maintenance (diesel)

- Power unit

- Gasoline engines

- Diesel engines

- Engine overhaul

- Cooling and heating

- Fuel system (gasoline)

- Fuel system (diesel)

- Engine electrical equipment

- Transmission

- Clutch and drive shafts

- Mechanical gearbox

- Automatic gearbox

- Chassis, running gear

- Brake system

- Car suspension

- Steering

- Body and interior

- Exterior (external elements)

- Interior (internal elements)

- Doors, locks and windows

- Electrical equipment

- Equipment and devices

- Electrical circuits

- General information

- User manual

- Maintenance

- Power unit

- Petrol engines 1.4 l

- Petrol engines 1.6-2.0 l

- Diesel engines

- Ignition system

- Fuel system (carburetor)

- Single point fuel injection

- Multipoint fuel injection

- Cooling and lubrication system

- Exhaust system

- Transmission

- Clutch

- Manual gearbox MA

- Manual gearbox BE

- Automatic gearbox

- Drive shafts

- Chassis, running gear

- Steering

- Front suspension

- Rear suspension

- Brake system

- Body and interior

- Exterior (external elements)

- Interior (internal elements)

- Doors, locks and windows

- Electrical equipment

- Equipment and devices

- Electrical circuits